Applications and advantages of ultrafast laser

Ultra fast laser applies to diamond, sapphire, glass,

semiconductor, metal, polymer and other materials precision fine machining.

Origin

Let the time back

to the 1980-1990 era, then all optical scientists in the laboratory of

painstaking design, adjustment of ultrafast laser transmission, focusing, try

to irradiation on a variety of materials, in order to find the moment of

arrival (they actually found a large number of unusual phenomena), they don't

think twenty or thirty after years of ultrafast laser processing workshop has

quietly entered the consumer electronics factory, entered the hospital to carry

out precise eye surgery, a key ring into the sophisticated components

manufacturing.

Today, many people around

the world are beginning to rely on ultra fast lasers because they can do many

jobs that conventional methods do not.

Application

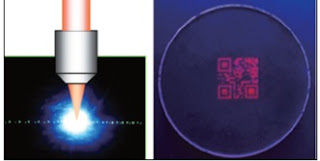

Ultrafast laser

called ultrashort pulse laser, its main characteristic parameters for the laser

pulse width from several to 10 femtosecond picosecond pulse repetition

frequency, from single pulse to 100MHz, laser wavelength from UV to ir.

After nearly 30 years of research and

development, ultra fast laser non hot and cold processing attributes began to

be loved. It is suitable for the machining of high precision and complex shape

devices which can not be realized by other processing methods. Ultrafast laser

micromachining of the main principle is the use of ultrafast laser pulse

focusing "focus" and the material nonlinear interaction, the minimum

can induce photochemical changes in sub wavelength to the nanometer scale and

the local material properties changed by computer pattern generation and

"focus" scanning, multi beam interference and self coherence etc. the

way, micro structure, micro device fabrication.

The advantages of

ultrafast laser micromachining are summarized as follows:

The suitable

materials of broad spectrum, especially difficult processing materials.The

photon energy of ultrafast laser beam is highly concentrated in time, after

focusing power density can reach a very high value, the use of ordinary

commercial ultrafast laser can induce an easy job to do almost any material

molecular bonds break and ionization state, and physical property variation

caused by the irreversible phase transition provides a physical basis for

ultrafast laser material processing.Due to the high strength, ultrafast laser

processing has a broad spectrum of materials, including diamond, sapphire,

glass, semiconductors, metals, ceramics and polymers and other materials.

The processing

precision is high, suitable for the preparation of complex 3D structures.Due to

the nonlinear absorption processes such as multiphoton absorption cross section

is very small, light excitation in the focal region of bounded minimum

detention area; in addition, due to the excitation of ultrafast, avoid thermal

relaxation, so ultrafast become a quasi adiabatic process, and light as an electromagnetic

wave is different from the real particle wave, can penetrate the transparent

material, processed from the inside.These guarantee ultrafast laser processing

with high three-dimensional processing resolution, even exceeding the optical

diffraction limit, to nanometer scale.

The non mask

technique, suitable for non planar processing.Ultra fast laser micro machining

is controlled by computer program, and is scanned in accordance with the

drawings of the structure to be processed.The pattern definition does not

require mask assistance, and is a non mask micro nanofabrication

technique.Without the mask, the laser focus can be scanned by the optical

surface, and the microstructure is fabricated on the non flat surface

substrate.

At present,

ultrafast laser micro machining has been widely used in consumer electronics,

Bio Medical, aerospace, information technology, new energy, new materials and

other industries.The processing techniques include drilling, scribing,

slotting, surface texturing, surface modification, internal modification,

welding, finishing, cleaning, etc..Around these ultrafast laser processing

technology, industry chain related enterprises and research institutes are

developing more stable performance, low cost and ultrafast laser device, beam

shaping space transmission technology, combined with the optimal processing

technology of material properties and manufacturing technology and intelligent

control of.

Market

According to the

special study on photonic and laser industry Strategies Unlimited predicts that

the global sales laser market in 2019 will reach $12 billion, while the total

market of ultrafast laser will exceed $1 billion 400 million, the market growth

rate is the ultrafast laser laser market grew two times as fast.The growth rate

of femtosecond laser is larger than picosecond laser.The gap between the two is

shrinking, which will lead to the use of femtosecond lasers in picosecond laser

applications.

Extending from the

perspective of industry chain, the laser industry should look like this, the

laser output value of 1 billion yuan, 5 billion yuan output value of the laser

processing system to the application to provoke the output value of 50 billion

yuan, so that by 2020 up to the size of the ultrafast laser industry chain to more

than $70 billion of the scale.As early as 2010, the United States Raydiance

company (acquired by Coherent in 2015) President Scott Davidson predicted that

in 10 years, ultrafast laser technology will have more than $100 billion

market, and now his prediction is becoming a reality.

Domestic and

foreign companies engaged in ultrafast laser device manufacturing and ultrafast

laser micro processing technology have sprung up to seize the emerging market

of ultrafast laser micro processing.Although there are a number of companies

developing femtosecond laser devices both at home and abroad, Tom Hausken,

chief analyst at Strategies Unlimited, thinks"...More value, that is,

significant revenues and profits, comes not from lasers, but from systems built

around lasers.Therefore, there are many opportunities here......".

At present, around

the ultrafast laser industry domestic and foreign mergers and acquisitions

after another, the laser and optoelectronics industry giants layout, the

ultrafast laser industry chain enterprises implementing mergers and

acquisitions in recent five years, nearly twenty mergers and acquisitions have

been implemented, you Changba me play, the next few years, people will see more

mergers and acquisitions.

Although it has

infinite bright future for the development of ultrafast laser micromachining,

but should be aware that the current mature ultrafast laser applications market

is very limited, with a large number of companies and into the pursuit of

capital, will cause the early industrial overheating will also usher in the

bottleneck of industrial development and even short-term slump.But in the near

future, with the development of more applications, a broader market will

emerge, and ultrafast laser micro machining will flourish for a long time.

Comments

Post a Comment